|

Spot

welding swivel Spot

welding swivel

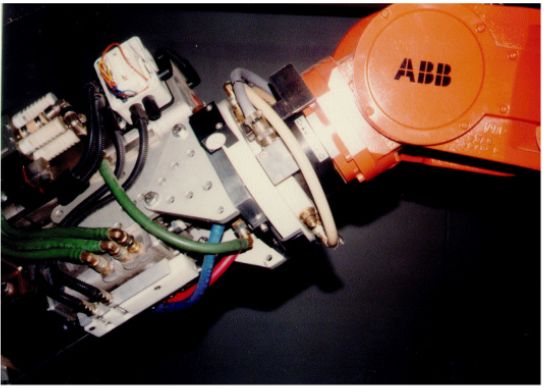

A major advancement in resistance spot welding is the swivel. This unit

permits passage of compressed air, cooling water, electric current and signals

through different channels within a single rotating unit.

This invention greatly improves total efficiency of robotic spot-weld

installations. Electrical connection between swivel and transformer is minimal

thus permitting maximum utilization of access to spot-weld areas.

|

|

Basic advantages are:

-

Less work space needed -No mass of cables and hoses hanging from the robot

arm, resulting in floorspace economy.

-

Improved accessability - Since no limitation on the robot wrist caused by

any cables or hoses.

-

Improved safety - Greatly improved safety factors through reduction of

air, electric and water lines; now limited to quick-connect piping, and

hoses within robot arm.

-

Saving in capital equipment - Compact weld-gun assembly accessable to

areas formly blocked by transformer, cables, and controlboxes. More welds

per station means big savings through fewer work stations and less capital

equipment.

-

Reduced try-out costs - No un-defined cables exist on the robot, which

reduces programming time to minimum. True off-line programming is now a

reality.

|

|

The swivel,

which fits directly onto the weld-gun fixture plate without any hoses or cables,

ensures the highest quality condition of the spot-weld. No electrical

degeneration on cables and no hoses that wear.

|

|

|